Smart Farm

Using ICT, Composite Livestock Management System

- Smart farms are intelligent farms that can remotely or automatically maintain and manage the growing environment of crops and livestock by incorporating IoT, big data, AI, automated systems, and robot technologies into facility horticulture (vinyl, glass greenhouses), livestock, etc.

- Introduction effects : Feed cost 9.2%↓, Employment cost 6.6%↓, Delivery rate 2.5%↑, Fine grade birth 6.9%↑, Disease emergence damage 43.9%↓(‘16, SNU)

-

- Environmental

management - Temperature, Humidity, CO2, Environmental monitoring and Automatic control of facilities

- Environmental

-

- Disaster

prevention - Livestock Safety Management(Arc, Fire, Power outage and Intrusion, etc)

- Disaster

-

- Specification

Management - Livestock Specification Management(CCTV monitoring, Water supply check, etc)

- Specification

-

- Operations

Management - Big Data Analysis(Sensors, Water Supply, etc. Data Base and farming journal)

- Operations

Smart Farm Products Group

Environmental management

- Internal environmental management equipment : Temperature, Humidity, CO2, Illumination, Ammonia, Carbon dioxide, Leakage detection, etc.

- External environmental management equipment : Temperature, Humidity, Wind direction, Rainfall, Solar radiation, Wind speed, etc.

Disaster prevention

- Safety management : Leak detection sensor, Electrostatic sensor, Fire detection sensor, etc.

Specification Management

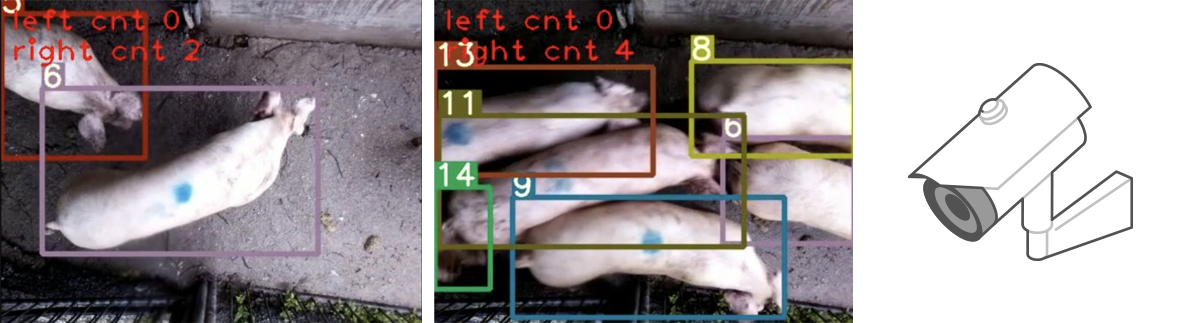

- Productivity Management : It is possible to check the number and condition of individuals according to livestock movement through CCTV.

Check Object Quantity

Operations Management

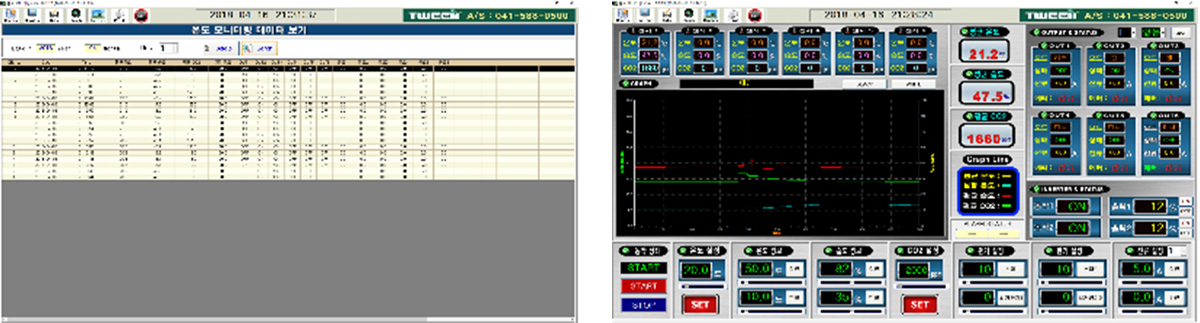

- Data Analysis : Analyze the livestock environment(Temperature, Humidity, etc) data to provide the optimal environment

Data Management and Analysis

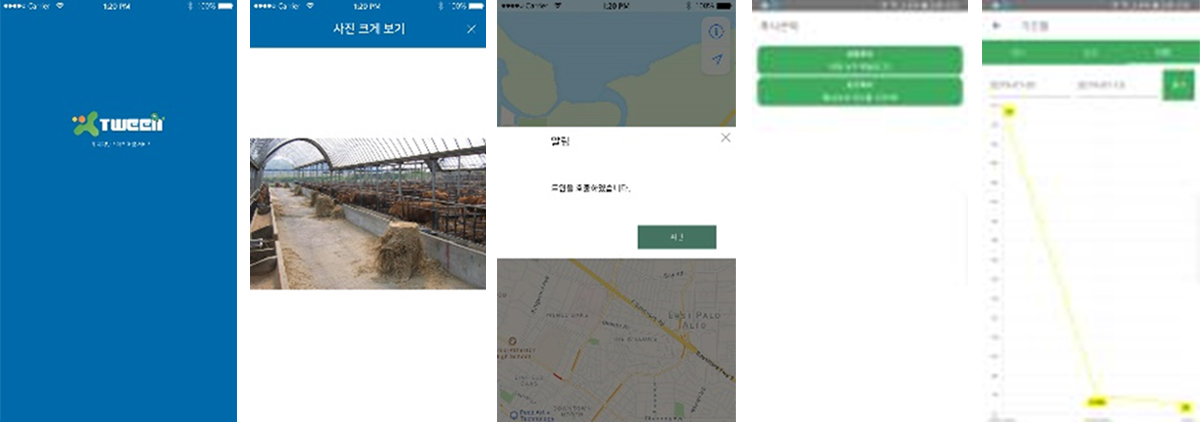

Farm management application

Farm Agriculture

- Agriculture, which relied on farmers' experience and knowledge, aims to increase productivity and added value by Intelligence based on advanced ICT technologies and minimize the input of materials and labor.

- Establishing a production system for agricultural industries to address issues such as climate change (change of cultivated land, natural disasters), worsening supply and demand of agricultural products (COVID-19, strengthening protectionism, etc.), diversifying agricultural and food demand, and shortage of rural manpower.

Smart Farm Gardening

- Hydroponics and Nutriculture

- Soil cultivation : Use of animal and plant culture media as soil(inorganic matter + organic matter)

- Soil cultivation + Nutriculture : Method of supplying nutrients from land to irrigation facilities

- Hydroponic cultivation : Method of supplying liquid to a medium-free or inorganic medium

Smart Farm (Fruit Tree) Hydroponics

Nutriculture

- Method of growing plants by artificially supplying nutritional water necessary for vegetation in various medium or non-medium conditions other than soil.

- Avoiding replant failure

- Automatic control of the underground environment

- Clean cultivation is possible

- Drastic reduction in labor force(Farming, Supplying organic matter, Weeding, Disinfection of medium, etc

- Selling advantage as a high quality or clean product

- Functional foods and vegetables can be produced

-

- Smart Farm Hydroponic

cultivation of fruit trees

(Tomato)

- Smart Farm Hydroponic

-

- Smart Farm Hydroponic

cultivation of fruit trees

(Strawberry)

- Smart Farm Hydroponic

-

- Smart Farm Hydroponic

cultivation of fruit trees

(Grape)

- Smart Farm Hydroponic

Precautions when Nutriculture

- Nutriculture is a nutrient that is supplied to crops, and each crop has a nutrient supply condition, and sensors such as EC, pH, and geothermal temperature are the standard of measurement the nutritional status of the crops, providing the necessary amount according to the sensor data.

- In order to control EC, pH, geothermal temperature, etc., the mixing ratio of the nutrients is changed.

- In the case of the Nutriculture information sensor, the drainage sensor or the culture medium sensor shall be installed selectively after consultation with the farmer.

- Nutriculture amount information sensor selects either the drainage information sensor(Drainage EC sensor, Drainage pH sensor) or the culture medium information sensor(the percentage of water content in culture medium, culture medium temperature sensor)

Product specification

| Product Name | Control box |

|---|---|

| Model Number | TW001-500DB |

| Specifications and Quality of the material(In case of SW, the medium used) | Standard : 200 × 300 × 185 mm Material: plastic (ABS) molded box |

| Main function |

|

| Product photo (SW case menu structure diagram) |

|

| Product Name | Double-blade ventilation fan |

|---|---|

| Model Number | TW001-500D2F |

| Specifications and Quality of the material(Program for SW) | Specifications: Length 905 mm, External diameter 510 mm, Internal diameter 500 mm Material: ABS |

| Main function |

|

| Product Photo (Replace with menu structure diagram when software) |

|

| Product Name | Central Control Unit (TWEEN) |

|---|---|

| Model Number | TW002-C01 |

| Specifications and Quality of the material(Program for SW) | Specification: 440 × 345 × 210 mm Material: Plastic (ABS) Forming Box |

| Main function |

|

| Product Photo (Replace with menu structure diagram when software) |

|

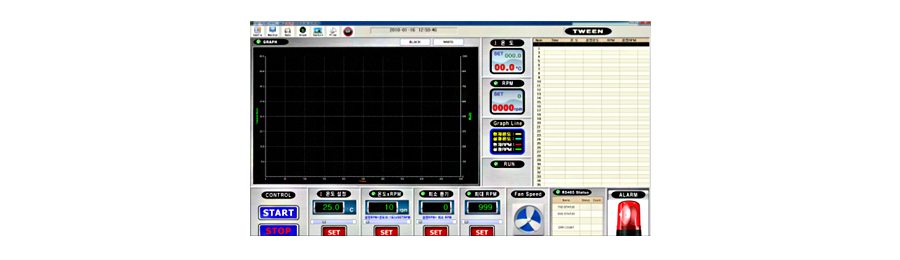

| Product Name | Ventilation system monitoring program (Selection Specifications) |

|---|---|

| Model Number | TW001-500DP |

| Specifications and Quality of the material(Program for SW) | Development language: Visual Basic 6.0 Monitor resolution: FHD (1920x1080) |

| Main function |

|

| Product Photo (Replace with menu structure diagram when software) |

|

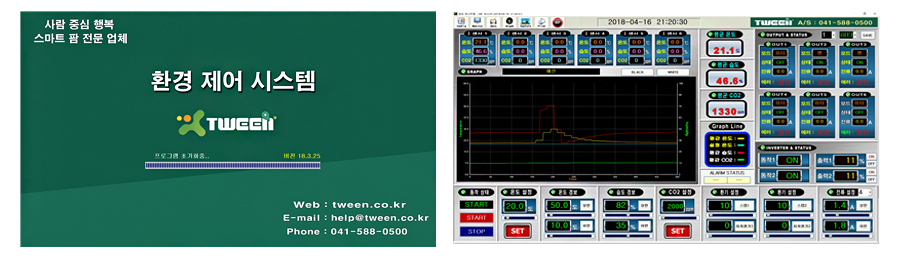

| Product Name | Environmental control program(TWEEN) |

|---|---|

| Model Number | TW002-CP01 |

| Specifications and Quality of the material(Program for SW) | IBM-compatible PC, Windows |

| Main function |

|

| Product Photo (Replace with menu structure diagram when software) |

|

| Product Name | Smart Heater |

|---|---|

| Model Number | TW-1911 |

| Specifications and Quality of the material(Program for SW) |

|

| Main function |

|

| Product Photo (Replace with menu structure diagram when software) |

|